This post is also available in:

![]()

Among all the people who operate a 3D printer, there is no one who has not at least once the nozzle of the 3D printer was clogged. Every time a clogged nozzle is very annoying and cleaning it can sometimes be quite troublesome.

But why does the nozzle of a 3D printer actually clog? The most common reasons for a clogged nozzle are dirt and filament debris, as well as particles of abrasive filament. Generally, the smaller the diameter, the more likely the nozzle will clog. Other causes can be printing too hot, an incorrectly calibrated print bed or technical problems.

As annoying as a clogged nozzle may be, in most cases the problem can be fixed in a short time. Sometimes, however, this can make the nozzle permanently unusable.

Why does the nozzle of a 3D printer clog?

There are several reasons why the nozzle of the 3D printer can become clogged. The reasons are mostly the following:

- Dirt in the nozzle

- Particles or fibers of abrasive filaments in the nozzle

- an inappropriately chosen nozzle diameter

- too hot printing

- Change from a material to be printed hot to a material to be printed cool

- a poorly calibrated print bed

- a poorly assembled printhead

Dirt in the nozzle

Dust and dirt can collect on the outer webs of the filament roll due to incorrect storage, among other things. If the filament is not cleaned before being fed into the printhead, this dirt can cause the nozzle to become clogged.

To prevent this from happening, it is recommended that the filament be cleaned before feeding it into the printer. For this purpose, for example, this print template and a piece of a household cleaning sponge can be used.

Particles of abrasive filaments in the nozzle

Abrasive filaments are all those filaments where particles or fibers have been mixed into the material. Examples are Glow-in-dark, Woodfill, Comperfill, Stonefill or the like. On the one hand, these abrasive filaments can cause the nozzles to wear out. On the other hand, the fibers and particles contained in them can build up in the nozzle and cause it to clog. Especially when printing with finer nozzle diameters such as 0.3 mm, 0.25 mm or smaller, the chance of clogging the nozzle with these filaments is very high.

Improperly selected nozzle diameter

The smaller the nozzle diameter, the greater the risk of clogging. As mentioned in the previous point, this is especially true for abrasive filaments. Especially with smaller diameters, the particles and fibers of these filaments can very easily lead to clogging of the nozzle.

But that is only one possible cause. The likelihood of the nozzle becoming clogged with dirt is also much higher with smaller nozzle diameters.

Printing too hot

If filament is printed much hotter than specified by the manufacturer and a slow print speed is selected, then the filament in the nozzle can more or less burn and thus clog the nozzle.

However, this does not necessarily mean that, as described in this blog entry, the nozzle automatically clogs at a higher temperature. This statement refers primarily to standard brass nozzles. If you print with a special nozzle, e.g. made of hardened steel, then you need even the higher temperatures to ensure the correct condition of the filament during printing. This is due to the respective material of the nozzle. For all these special nozzles, unless the manufacturer provides approximate information, you will have to try to find the optimum temperature range yourself.

Change from a material to be printed hot to a material to be printed cool

If material is printed in a higher temperature range, e.g. nylon or PET-G, and then changed to PLA, which is printed much cooler, there may still be residues of the old material in the nozzle. If these remnants are not completely printed out of the nozzle in the course of the filament change, these remnants can block the new “cooler” material and prevent this material from being printed cleanly. Over time, this can cause more and more material to build up there and then lead to a clogged nozzle.

I address this and some other aspects in my blog, which deals with the question of the usefulness of separate nozzle sets per material type.

Poorly calibrated print bed

Due to a poorly calibrated print bed, in this specific case when the nozzle is too close to the print bed, not enough material can be printed through the nozzle in the course of printing. Since the material in the printhead is heated anyway, this can lead to too much melted material in the printhead after some time and this clogs the nozzle.

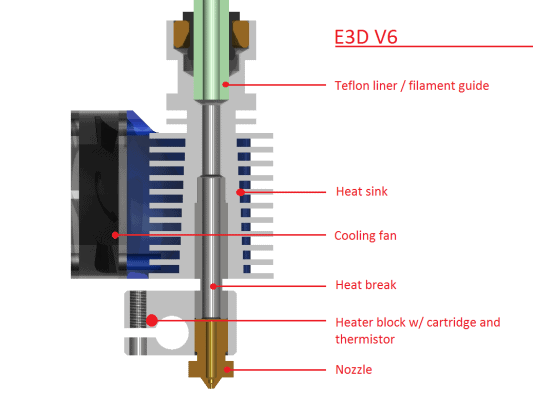

A poorly assembled printhead

A poorly or incorrectly assembled printhead will not necessarily result in a clogged nozzle, but it will result in a clogged printhead. Since the problem is very similar, I would like to make this point here as well.

A poorly assembled printhead can cause the filament to become too warm in the wrong place in the printhead. This usually results in the filament becoming so soft that it can no longer be properly conveyed to the die and extruded. Initially, this problem manifests itself as under-extrusion , and then at some point the nozzle or print head becomes completely clogged.

In the case of printheads that have a PTFE tube inside them, it is possible that this PTFE tube does not go all the way inside. Here, the filament becomes too warm in the wrong place and can lead to clogging of the printhead.

Sometimes the problem is due to the fact that the distance between the heat sink and the heater (hotend) is too large. That’s how it was in 2020 for many people, including me, who bought a Prusa Mini.

The hotend protruded a few millimeters too far from the heat sink and thus the distance between the two was too large. The filament was not cooled long enough and thus became too warm too soon. In the beginning, printing usually worked without any problems. After a few prints, however, underextrusion occurred more and more frequently until finally nothing worked at all. Since the problem had been known for some time at the time I got my print, there were fortunately instructions on how to fix this error.

How can I prevent the nozzle of the 3D printer from clogging?

Clogging of the nozzle cannot be completely avoided. You can only try to prevent clogging with various measures. You can do that by paying attention to the following:

- Clean the filament with a sponge before feeding it into the extruder. For example, you can use the following print template and a piece of cleaning sponge to pull through and clean the filament before feeding it into the extruder.

- For abrasive filaments, follow the manufacturer’s instructions. Sometimes manufacturers specify that you should only use the filament with nozzles above a certain diameter.

- Check that the PTFE tube is inserted all the way inside your hotend. Of course, this only applies if there is a PTFE tube inside your hotend.

- If your printer is new and the hotend is fully assembled, then it’s still worth taking a look and checking that everything is sitting as it should. Further you can google for known problems with printing. As in my case with the Prusa Mini, you can quickly come across error reports related to the printhead and how to fix them.

- When changing from hot-to-print filament to a cooler-to-print filament, you should extrude some filament first after feeding the new filament. This allows you to ensure, to a certain extent, that the previously used filament is completely transported out of the print head.

- What you can also do from time to time is to preemptively clean the printhead with cleaning filament.

Can I clean a clogged nozzle?

There are several ways to clean a clogged nozzle. By the following ways you can try to unclog the blockage in your nozzle:

- Heat the nozzle a little higher than usual for the respective filament. Wait a minute or two. In many cases, such as with the Prusa Mini, the filament runs out of the nozzle on its own after a short time. Otherwise, try using a piece of filament and a little pressure to push the filament through manually. You can definitely apply a little pressure here, but don’t overdo it to avoid worse damage to the printhead.

- Use a so-called cold pull. To do this, insert filament into your heated printhead and allow it to cool to about 80-90°C. Now try to pull the filament out of the nozzle or print head with a little force. Ideally, you will find some dirt in the cooled filament. Repeat this process 2-3 times.

- Heat up the printhead and try to loosen the blockage from the outside to the inside with a cleaning needle. Be careful not to burn yourself on the hot nozzle or the hot filament.

Alternatively, you can of course remove the nozzle and clean it outside the printer with a cleaning needle. However, you will need a suitable heat source for this, such as a hot air gun. - Try unclogging with cleaning filament .

Sometimes, however, the blockage may not clear at all. In this case, you have no choice but to change the nozzle. How to change a nozzle quickly and easily, I describe in this step by step guide. In addition, you will find an overview of different types of nozzles compiled in my recommended products. There you will also learn which nozzle you should best use for which filament.

Which filaments cause nozzles to clog?

In general, the nozzle can be clogged by any filament. Even switching from ABS or PETG to PLA can be a problem in the worst case. Here, residues of the old warmer filament can remain in the nozzle and block the new filament, which is cooler to print. Over time, this can lead to a clogged nozzle. Fortunately, however, this does not happen quite so often.

Nozzles tend to clog more when you use abrasive filaments with particles and fibers. The fibers or particles can block the fine nozzle outlets and eventually lead to clogging of the nozzle.

NOTE!

I have mentioned and linked some materials, tools and the like in this article. All these and other products that I can recommend without a guilty conscience, I have summarized for you in my recommended products. These are affiliate links and for each purchase through these links I get a small compensation from the respective merchant. If the various articles on the site have helped you and you would like to support this blog, I would be very happy if you use these affiliate links when you shop. Thank you very much.