This post is also available in:

![]()

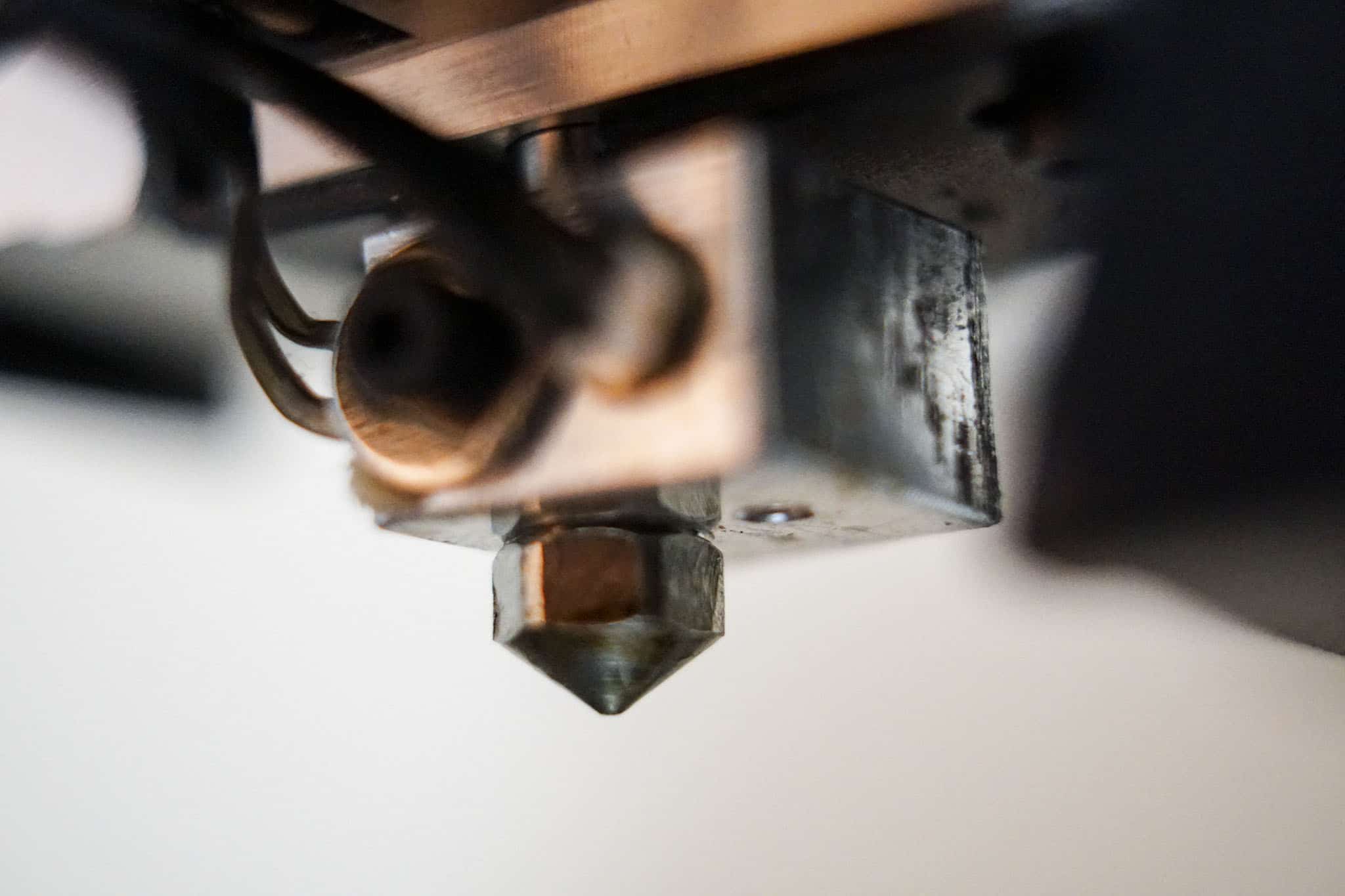

3D printers are usually equipped with brass nozzles at the time of purchase, as they offer the best heat transfer. However, brass is a very soft material and printing abrasive filaments can be quite hard on the nozzle.

But can 3D printer nozzles wear out? When printing exclusively with non-abrasive filaments such as PLA, ABS, PETG and the like, a nozzle will often last as long as the printer itself. With abrasive filaments such as Glow in dark, PC, Stone- or Woodfill, etc., which have fibers or particles incorporated into the filament, just a few 100 grams can be enough to render a nozzle unusable.

By using suitable nozzles for the respective material, it is possible to extend the service life of the standard nozzles. However, other nozzles also bring other problems.

Can 3D printer nozzles wear out?

Yes, the nozzles of a 3D printer can basically wear out. Whether they survive the lifetime of the printer or wear out very quickly depends on various factors.

If you print exclusively with filaments like PLA, ABS, nylon, and PETG, you’ll probably have a lot of fun with your nozzle for a long time. Of course, the quality of the nozzle and the filament used also play a not insignificant role here. The poorer the quality of the material of the nozzle or filament, the more likely it is that the nozzle will wear out faster.

If, on the other hand, you like to print more exotic filaments such as Glow-in-dark, PC, Woodfill, Sandfill, Coperfill, etc., then you will probably have to replace your nozzle more often. With these so-called abrasive filaments, which are mixed with carbon or glass fibers or other particles, just a few 100g are enough to wear out a nozzle to such an extent that you can no longer achieve good prints.

Why do the nozzles of a 3D printer wear out?

The nozzles of the 3D printer wear out simply due to friction. Even if the filament is melted in the hotend and thus assumes a more liquid state, friction still remains. If this surprises you, think of a stone river basin that has been shaped by water over the years.

The degree of nozzle wear depends on two factors. The material used for the nozzle and the filament used. The standard nozzles of most printers are made of brass. Brass is a relatively soft material. If mainly non-abrasive filaments such as PLA, ABS or PETG are printed, very little happens here over time.

However, if an abrasive filament is used more often, the fibers and particles of the respective filament will scratch or scrape across the surface of the nozzle. This leads to relatively rapid damage to the surface of the nozzle. Nozzles with poor material or workmanship quality can be completely defective here after very little material.

Nozzles made of harder material, such as hardened steel, brass nozzles with special coating or even nozzles with ruby tip, this wear does not occur as much, because the base material is much harder. But these special nozzles are also a little more expensive.

How can I tell that the nozzle is worn?

If your nozzle is worn, you will normally only notice it during or after the end of printing. Drops then form on the surface of the printout because more material is output by grinding out the nozzle. However, this does not mean that drops on the surface of the printout are automatically always due to a worn nozzle.

If you hold a new nozzle and a worn one of the same diameter side by side, you can even tell with the naked eye in some cases.

Can I prevent the nozzle from wearing out?

Well, completely prevent the wear of the nozzle is not possible. Even if you only print non-abrasive filaments such as PLA, ABS, etc., the nozzle will wear out over time. Not as strong as with abrasive filaments, but still.

What you can do is not use the standard brass nozzle when printing abrasive filaments, but use special nozzles. Here there are various nozzles such as brass with special coating, nozzles made of hardened steel or even brass nozzles with ruby tip.

So when you switch to a special nozzle, you help your standard brass nozzle last longer. The problem is, however, that this is very likely not without side effects. The coating or other material changes the heat transfer from the hotend to the nozzle or from the nozzle to the filament. This means that you may have to print much hotter and slower in some cases.

If you have switched to a special nozzle, however, that doesn’t mean you have to change the nozzle every time you print PLA and co. You can of course also print non-abrasive filament with these nozzles.

How to change a nozzle quickly and easily, I describe in this step by step guide.

Can I repair a worn nozzle?

If the nozzle has been abraded on the inside by printing abrasive filaments, then it will no longer have its original diameter. This diameter can no longer be restored. Therefore, the answer to the question is basically no.

What you can do, however, is drill out the nozzle. So, turning a 0.4 mm nozzle into a 1 mm nozzle. Whether reboring is an option for your specific case depends on how much the nozzle is worn and, of course, your craftsmanship.

However, if you are trying to drill out the nozzle, you really need to work very carefully and know what you are doing. A poorly drilled nozzle can cause the nozzle to clog very quickly and frequently during printing. Most of the time, these experiments are not worth it and buying a new nozzle is the smarter option.

Can I still use a worn nozzle?

The bottom line is that it depends a lot on the condition of the nozzle, but basically you can still reuse that nozzle. However, you must first find out here what the diameter of your nozzle is now. You can then set the new diameter in your slicer. Depending on the degree of deviation, you can either change the nozzle diameter or the extrusion multiplier.

If the nozzle is also ground down on the outside of the tip, you should definitely recalibrate the print bed, as the distance to the print bed is no longer correct due to the grinding of the tip.

Nevertheless, you should be aware that the worn nozzle will most likely affect the quality of your prints.

How long does it take for a nozzle to wear out?

When printing with standard brass nozzles and good quality PLA, ABS, PETG, the nozzle life can be several 1000 printing hours. However, cheap brass nozzles can also be worn out after just a few 100 hours of printing. When printing abrasive filaments with a standard brass nozzle, however, this can also be the end after less than 100 printing hours.

When using a high quality nozzle made of hardened steel, coated brass or brass nozzles with ruby tips, the nozzle life can be up to 4x as long or even longer according to the manufacturer.

How high can the wear of a brass nozzle be?

As already mentioned several times, the wear of the standard brass nozzles is kept within limits when printing non-abrasive filaments such as PLA, ABS, nylon and PETG. Depending on the stress and quality of the filament, the nozzle can last as long as the printer itself or even longer.

When printing abrasive filaments, the wear can be so high that after a few 100g of e.g. glow in dark filament, an original 0.4mm nozzle has a diameter of 1mm or higher at the end of the print. This wear can already become noticeable during the printing process for larger print objects. If your printer supports this feature, you can counteract here with live adjustment of the amount of material fed to a certain degree.

Is it worth having separate nozzles for abrasive filaments?

Absolutely. As mentioned, standard brass nozzles do not withstand the stresses of abrasive filaments for too long. Therefore, it is quite advisable to have special nozzles for printing abrasive filaments and to use them when necessary.

Note, however, that you will need to adjust the profiles of your slicer depending on the nozzle you are using. Some materials, e.g. hardened steel, require a pressure temperature up to 30°C higher than standard nozzles. The printing speed usually decreases with special nozzles. That means you have to print slower with special nozzles. Since the shape of the nozzle can also vary, you should always recalibrate the print bed after changing the nozzle.

NOTE!

I have mentioned and linked some materials, tools and the like in this article. All these and other products that I can recommend without a guilty conscience, I have summarized for you in my recommended products. These are affiliate links and for each purchase through these links I get a small compensation from the respective merchant. If the various articles on the site have helped you and you would like to support this blog, I would be very happy if you use these affiliate links when you shop. Thank you very much.